Search This Supplers Products:Refractory steel fiberRefractory castableRefractory anchorPolypropylene fibersteel fiberSteel wire

What are the types of Reinforcing Metallic Fibres (RMF) and their application with a refractory cast

ASTM Standard A820 has established three (3) classifications of stainless steel fiber which are as follows:

Benefits related to the use of metallic fibers include:

- Controlled and uniform cracking of the refractory lining

- Strength retention of the refractory lining,

- Minimize permanent linear change,

- Increased lining toughness

- Improved thermal shock resistance

Increased Lining Toughness

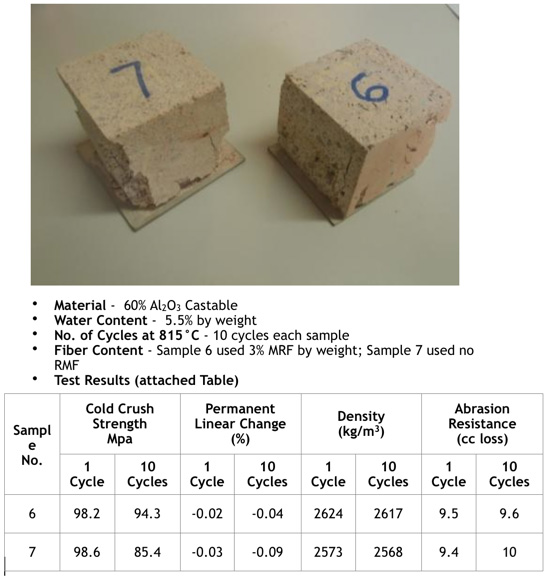

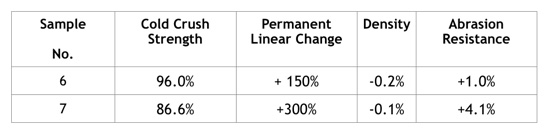

The effectiveness of metal reinforcing fibers related to toughness is based on a comparison of physical properties of the samples fired during one (1) cycle versus the physical properties of specimens taken from the test sample using no MRF and sample using 3% MRF. The strength retention as measured by cold crushing strength was higher for the sample using the MRF as compared the sample not using MRF after ten (10) cycles in the furnace.

The PLC for the sample using MRF was half as much as the sample not using MRF. While the abrasion resistance of the samples using MRF increased by 1% versus the 4% increase of the sample not using the MRF. The change in density between the two samples was minimal. The photo of the tow (2) samples shows a significant difference between the two samples after the cold crush test. Sample 7 showed fractures on the sides along with a breaking plane through the mid section of the sample whereas Sample 6 remained in one piece with visible cracking on the sides of the specimen with minimal material loss

The PLC for the sample using MRF was half as much as the sample not using MRF. While the abrasion resistance of the samples using MRF increased by 1% versus the 4% increase of the sample not using the MRF. The change in density between the two samples was minimal. The photo of the tow (2) samples shows a significant difference between the two samples after the cold crush test. Sample 7 showed fractures on the sides along with a breaking plane through the mid section of the sample whereas Sample 6 remained in one piece with visible cracking on the sides of the specimen with minimal material loss